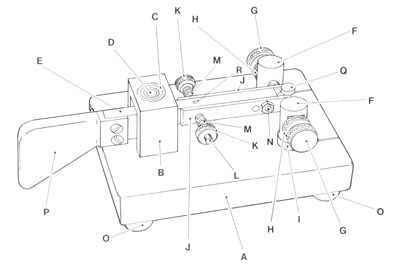

| Pre-assembled

base and bearings |

|

|

| (A) |

1 steel base |

(M) |

2 springs |

| (B) |

1 bearing block |

(N) |

2 3mm grub screws - long |

| (C) |

2 ball race bearings |

(O) |

4 rubber feet |

| (D) |

1 steel pivot pin |

(P) |

1 plastic paddle |

| (E) |

1 main brass arm |

(Q) |

1 centre stop pillar |

| |

3 3mm screws |

(R) |

1 3mm grub screw - short |

| |

2 3mm washers |

|

2 4mm screws - long |

| |

2 3mm solder tags |

|

3 4mm washers |

| |

1 3mm grub screw |

|

2 4mm solder tags |

|

|

4 3mm screws - short |

| (F) |

2 contact adjusting pillars |

|

5 3mm washers |

| (G) |

2 brass copper tipped screws |

|

2 brass screws |

| (H) |

2 knurled locking nuts |

|

1 4mm screw - short |

| (I) |

4 plastic insulators |

|

1 cable clamp |

| (J) |

2 copper tipped brass arms |

|

1 length of cable |

| (K) |

2 knurled spring adjusters |

|

2 3mm brass nuts |

| (L) |

1 spring adjusting stud |

|

1 allen key |

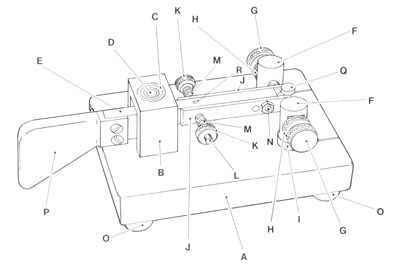

ASSEMBLY NOTES

Read all the instructions

before starting the assembly.

1. On the steel base fit

the four rubber feet onto the steel base using

the four 3mm screws and washers.

2. On the base assembly fit the spring tension

stud (L) into the main arm so that the stud

protrudes equally from each side. When in

position secure with the shortest of the 3mm

grub screws.

3. Fit the two contact arms (J) so the contacts

are positioned outwards, passing the arm over

the spring tension stud and locating the pin

in the contact arm into the slot in the main

arm. Secure using the springs (M) and the

spring adjusting nuts (K).

4. Fit the centre stop pillar (0) using a

3mm screw and washer

5. Fit the two contact

screws (G) together with the locking nuts

(H) into the pillars (F) so that the contacts

protrude by not more than 1/8fl. Ensure the

screws are assembled from the correct side

so the locking nut seats into the machined

flat in the pillar.

6. Fit the contacts and pillar assemblies

onto the base using the four plastic insulating

spacers (I) and the two long 4mm screws, having

first placed a solder tag and washer under

the screw heads. Before tightening the screws

align the contacts in the pillars with the

contacts on the moving arms. Vertical adjustment

is carried out by slackening the grub screw

in the end of the main arm using the allen

key supplied. Slide the arm (E) up or down

on the pivot pin and, when the contacts are

correctly aligned, re-tighten the grub screw,

It is advisable to make this adjustment at

this stage as access to the grub screw in

the main arm is not possible with the paddle

(F) fitted.

7. Fit the paddle (F) onto the main arm using

the two brass screws.

8. Cut back the outer protection on the length

of cable by approximately 3” then secure

on the underside of the base with the cable

clamp using the 4mm screw and washer.

9. Make the three solder connections, one

to each of the contact pillar solder tags

and one to the bearing block solder tag, together

with one end of a 1” length of the braided

wire supplied. Solder the other end of the

braided wire to the pivot pin solder tag.

10. Finally start the two 3mm grub screws

and nuts (N) into the contact arms. At this

stage do not allow them to protrude on the

inside of the brass arm.

Setting Up

Using the Allen key supplied screw each of

the 3mm grub screws in arms (J) inwards a

little at a time so that when the paddle is

moved from side to side the contact arms immediately

respond with no play.

Note:

(1) If screws are too far out there will be

play between the contact arms and main arm.

(2) If the screws are too far in there will

be play between the contact arms and the centre

pillar.

Keep adjusting the grub screws from each side

until correct then tighten the locking nuts.

Finally adjust the contact gaps and spring

tensions to your requirements.